Summary

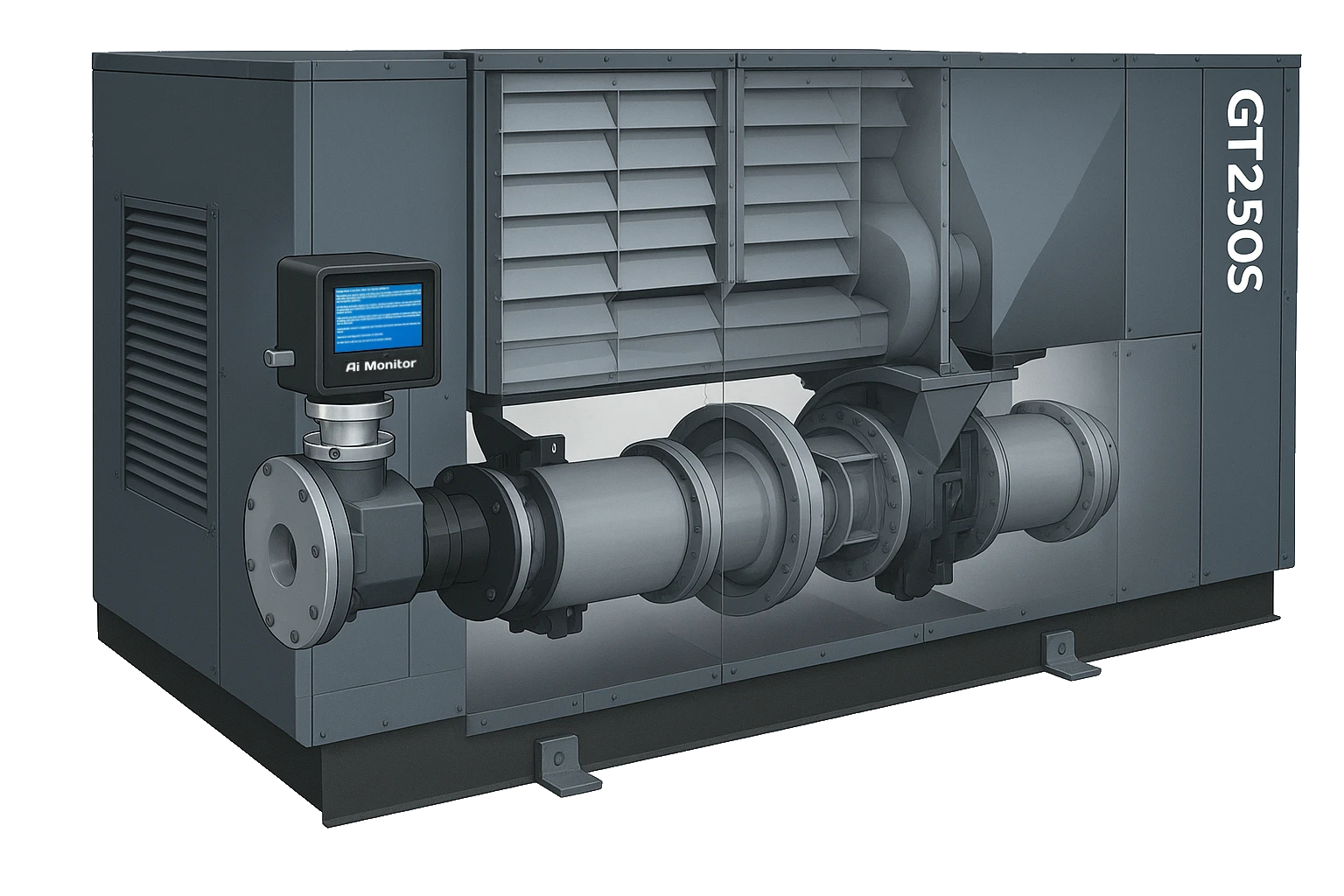

This white paper discusses on-site clean energy backup power generation systems that increase system availability, allow fuel flexibility, lower costs, and reduce operations and maintenance (O&M) requirements compared to legacy systems that utilize diesel power or conventional battery backup. In particular, we examine clean energy systems that operate using multiple gaseous fuel types including natural gas (NG), sour NG, acid gas, hydrogen and more — thus diversifying fuel supply and future-proofing backup generation assets. One such example includes the FlexEnergy's 250 kW Flex Turbine® GT250S — one of the smallest U.S. made, fuel-flexible turbine genset available for clean energy backup and/or distributed power applications.

Technical Background

Flex-fuel turbine generator sets (gensets) offer a versatile and resilient power solution for civilian and military backup needs in the 200 kW to 1 MW range, addressing a multitude of operational requirements.

Industrial applications of gas turbines for power generation

1. Multi-Fuel Flexibility: Beyond Traditional Battery Backup

Unlike conventional battery backup systems with limited discharge time, flex fuel turbines can operate continuously on diesel, jet fuel (JP8), natural gas, hydrogen, or ammonia, ensuring uninterrupted clean energy power even during extended fuel supply disruptions. Their advantages over battery backup include:

- Reduction in fossil fuel dependency through the ability to utilize renewable fuel sources

- Future-proofing infrastructure by enabling a transition to hydrogen and other clean energy carriers as these markets mature

- Extended runtime capability without the degradation concerns inherent to battery backup solutions

- Enhancing mission readiness in remote or challenging environments where fuel availability and battery charging capability may be unpredictable

Interior view of a modified flex-fuel turbine generator with Ai assisted monitoring.

2. Operational Resilience and Reliability

- Proven durability: Turbine engines like the Lycoming T53 (TM1000) have over 40 million hours of operational history in aviation and industrial applications.

- Continuous duty cycles: Designed for 24/7 operation with minimal vibration and maintenance.

- Decentralized architecture: Smaller, distributed gensets improve resilience compared to centralized systems, as highlighted in recent military microgrid studies.

3. Efficiency and Emissions Compliance

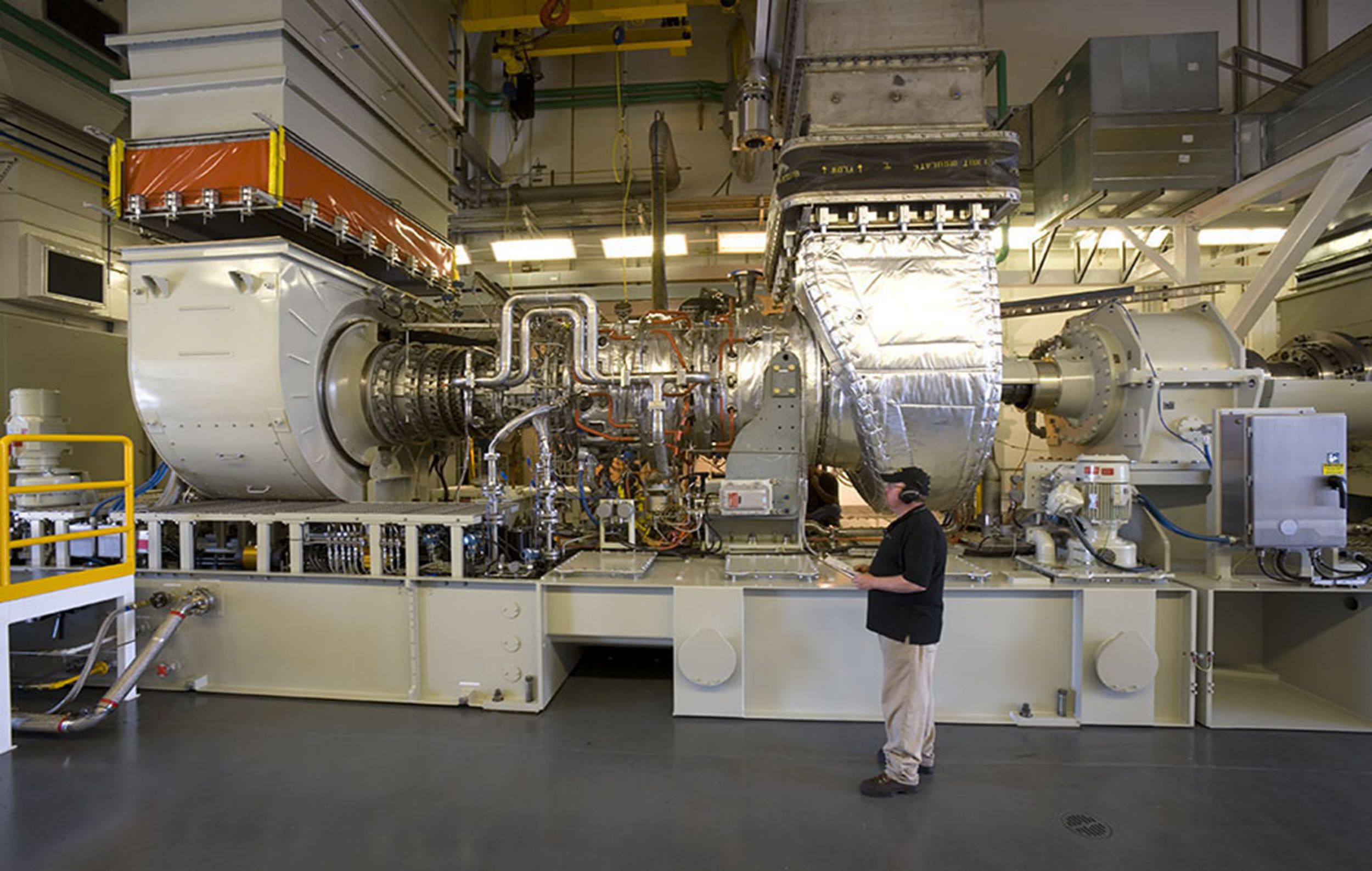

- High efficiency: Aeroderivative turbines like GE's TM2500 achieve greater than 39% efficiency, outperforming legacy diesel generators.

- Low emissions: Flex-fuel turbines produce ≤10 ppm NOx/CO (vs. reciprocating engines), aligning with environmental regulations and reducing detectability in tactical scenarios.

GE's TM2500 aeroderivative gas turbine for mobile power generation

4. Mobility and Adaptability

- Compact design: Units like the TM1000 and PCI's tactical gensets are lightweight, portable, and self-contained, ideal for rapid deployment.

- Integration with military systems: Features like 24VDC compatibility, remote monitoring, and camouflage coatings ensure seamless operation in diverse environments.

5. Cost-Effectiveness

- Lower lifecycle costs: Decentralized systems with smaller turbines reduce fuel consumption and maintenance expenses compared to large diesel generators.

- Scalability: Modular designs (e.g., GE's TM2500) allow incremental power additions as needs grow.

Case Studies and Pilots

- The U.S. Department of the Air Force is piloting Mainspring Energy's 125/230 kW linear generator at Travis AFB, testing hydrogen/ammonia compatibility for carbon-free power generation.

- A capstone study at the U.S. Naval Postgraduate School examined the cost and resilience of centralized and decentralized power architectures by developing a general methodology to capture comprehensive life-cycle costs and metrics. The capstone then applied this methodology to the aging diesel generator power plant at Naval Station, Rota, Spain, which demonstrated that decentralized architecture was the most cost-effective strategy for resilience.

Mainspring Energy linear generator being tested for military applications

Comparison to Traditional Diesel Generators

| Feature | Flex-Fuel Turbine | Traditional Diesel |

|---|---|---|

| Fuel options | Multi-fuel (diesel, JP8, H₂, NH₃) | Diesel only |

| Emissions | ≤10 ppm NOx/CO | Higher NOx/particulates |

| Resilience | Decentralized, modular | Centralized, single-point failure risk |

| Maintenance | Lower (fewer moving parts) | Higher (complex engine systems) |

| Future readiness | Compatible with emerging fuels | Limited adaptability |

Analysis of Turbine Genset Solutions

Several U.S. companies offer fuel-flexible gas turbine gensets suitable for use as backup power generators. The following table depicts the most notable options and their relevant features:

Feature Comparison

| Company | Model/Offering | Fuel Flexibility | Key Features/Notes |

|---|---|---|---|

| FlexEnergy | Flex Turbine Series | Wide gas range (350–2500 Btu/SCF), sour/acid gas, up to 30% H2 | Designed for backup and continuous power, can use flare, vent, and low-pressure gases. |

| GE Vernova | TM2500, others | Runs on various gaseous and liquid fuels | Mobile, trailer-mounted, rapid deployment for emergency/backup power; extensive fuel flexibility. |

| Solar Turbines | SMT60, SMT130, Centaur 40, others | Wide fuel composition, including H2 blends | Mobile, rapid setup, designed for emergency/backup and remote power; proven in data centers, oil & gas. |

| OptiFuel Systems | Total-Zero™ Hybrid Power Generators | RNG, CNG, pipeline gas, modular hybrid options | Designed for standby/backup and microgrids, modular, rapid deployment, low emissions. |

FlexEnergy, GE Vernova, Solar Turbines, and OptiFuel Systems all offer fuel-flexible gas turbine gensets that can be deployed as backup power generators in the U.S. Each company provides models with varying degrees of fuel flexibility, rapid deployment capabilities, and suitability for emergency or standby power applications.

Solar Turbines gas turbine package for industrial and backup power applications

Comparison Summary

| Manufacturer | Smallest Fuel-Flexible Turbine Genset | Fuel Types Supported | Notes |

|---|---|---|---|

| FlexEnergy | 250 kW Flex Turbine® | NG, sour gas, acid gas, H₂ blends | Broadest fuel flexibility, commercial use |

| Capstone | 30 kW C30 | NG, biogas, propane, H2 blends | Smaller, but less focus on sour/acid gas |

| FusionFlight | 8 kW ARC | Diesel, Jet-A, kerosene, biodiesel | Specialty, not standard genset |

FlexEnergy turbine for off-grid power systems and backup applications

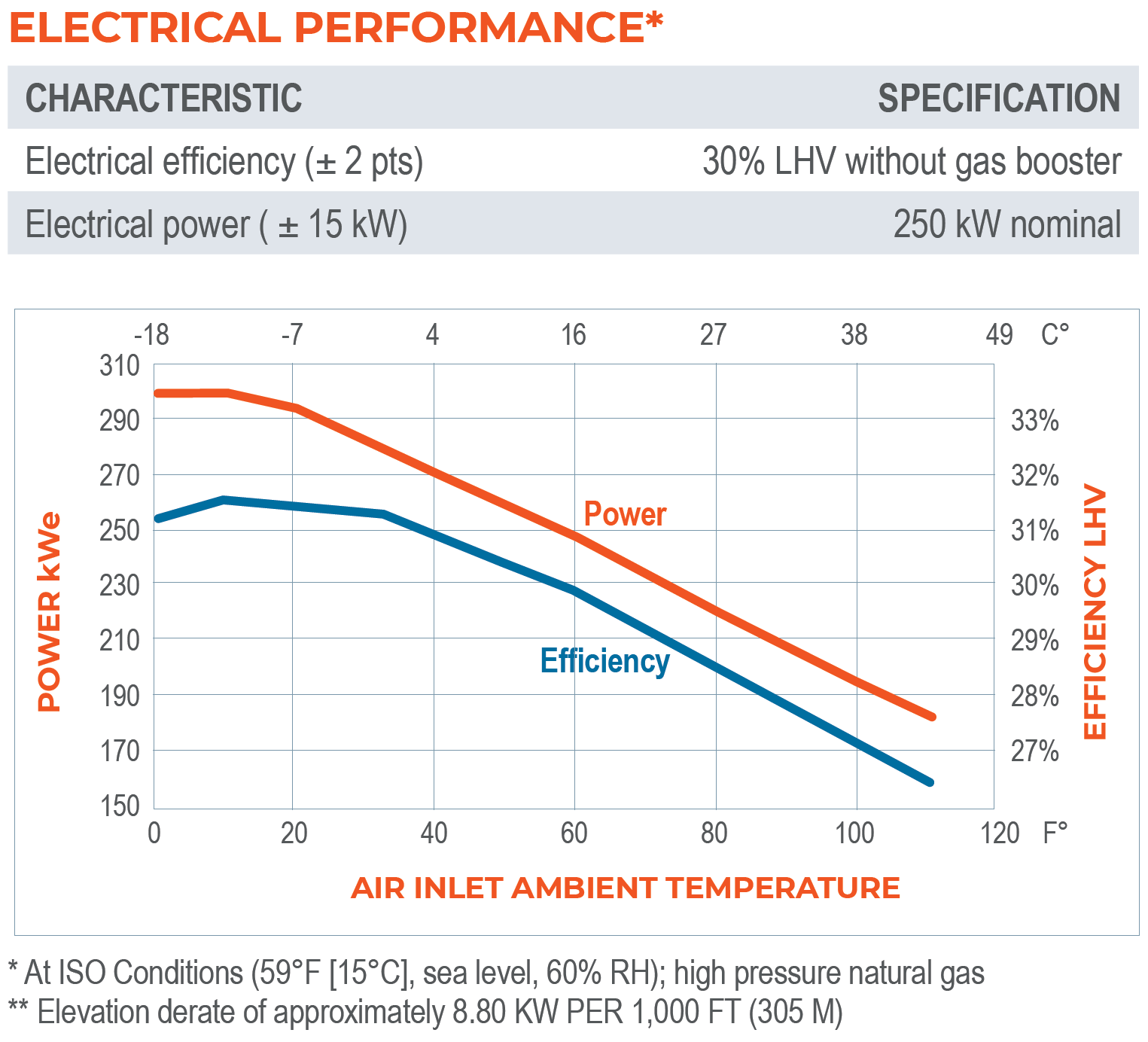

FlexEnergy 250 kW Flex Turbine® GT250S Specifications

Capacity Factor

The turbine is designed for continuous operation (base load or backup), so the capacity factor depends on user application. Technically, it can operate at 100% capacity factor if run continuously.

Modular Design

These units are marketed for backup and continuous power and readily deployable as modular systems to provide higher capacity outputs.

Gas Flow Rate

Fuel flexibility: Accepts a wide range of gaseous fuels (natural gas, sour gas up to 6,500 ppm H₂S, acid gas up to 70% CO₂, up to 30% hydrogen blends).Typical natural gas consumption at full load (250 kW):

- Heat rate (LHV): 11,380 Btu/kWh (without gas booster)

- Total gas input per hour: 250 kW × 11,380 Btu/kWh = 2,845,000 Btu/hr

- Gas flow rate per minute: 47.4 ft3/min (SCFM)

Efficiency vs. Load

Electrical efficiency (LHV, ISO conditions):- At full load (250 kW): 30–31%

- Efficiency is highest at or just above nominal load (250 kW), and drops slightly at lower loads.

- At 150 kW: ~28%

- At 190 kW: ~29%

- At 210 kW: ~30%

- At 250 kW: ~31%

- At 290 kW: ~32–33% (above nominal rating, for reference only)

Representative gas turbine efficiency curve showing relationship between load and efficiency

Specs Summary

| Parameter | Specification/Range |

|---|---|

| Rated Output | 250 kW continuous |

| Capacity Factor | Up to 100% (continuous operation possible) |

| Gas Flow Rate | Approximately 2,845 ft³/hr (natural gas, full load) |

| Electrical Efficiency | 30–31% (LHV, full load); decreases at lower loads |

| Fuel Flexibility | NG, sour gas, acid gas, up to 30% H₂, 350–2,500 Btu/SCF |

| Price (new unit) | About $195,000 USD |

Conclusion

The FlexEnergy 250 kW Flex Turbine® GT250S power generation solution provides both technically and economically best solution for back-up power generation where a variable source of feed gas is available. Its combination of fuel flexibility, reliability, and efficiency makes it an excellent choice for organizations looking to future-proof their backup power infrastructure while reducing environmental impact and operational costs.